The process of converting raw cotton into yarns, fabrics & garments requires even more water. Dyestuffs & chemicals deplete & pollute the limited fresh water around production facilities, & are a major contributor to CO2 emissions.

Textile production today is one of the most environmentally detrimental industries in the world. Producing yarns, fabrics and garments requires a tremendous amount of resources, and creates a lot of textile waste in the process.

De-Carbon Headwear with a fully compliant production facility that spans over an area of 15000 sft and with a production capacity of 500000 caps per month is working towards reducing your carbon footprint, to preserve the eco system for the future generation.

"The item was compared to the equivalent yarn in the most commonly used composition produced in the same country-recycle cotton compared to conventional cotton / recycle polyester to virgin ployester / ecovero viscose to conventional viscose in an open loop process. The processes and transportation used were based on the most commonly used in the industry and in Bangladesh."

Textile production today is one of the most environmentally detrimental industries in the world. Producing yarns, fabrics and garments requires a tremendous amount of esources, and creates a lot of textile waste in the process.

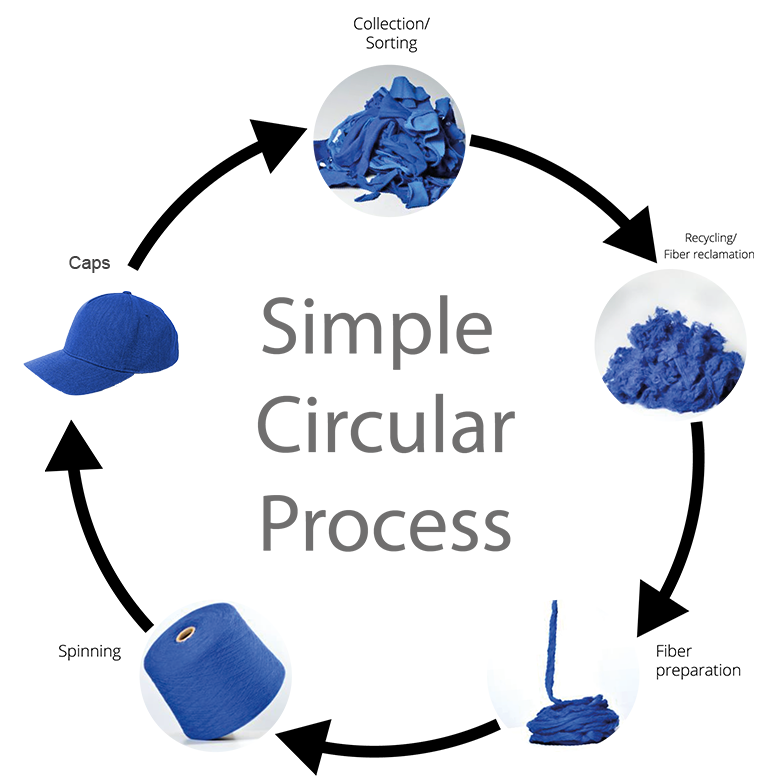

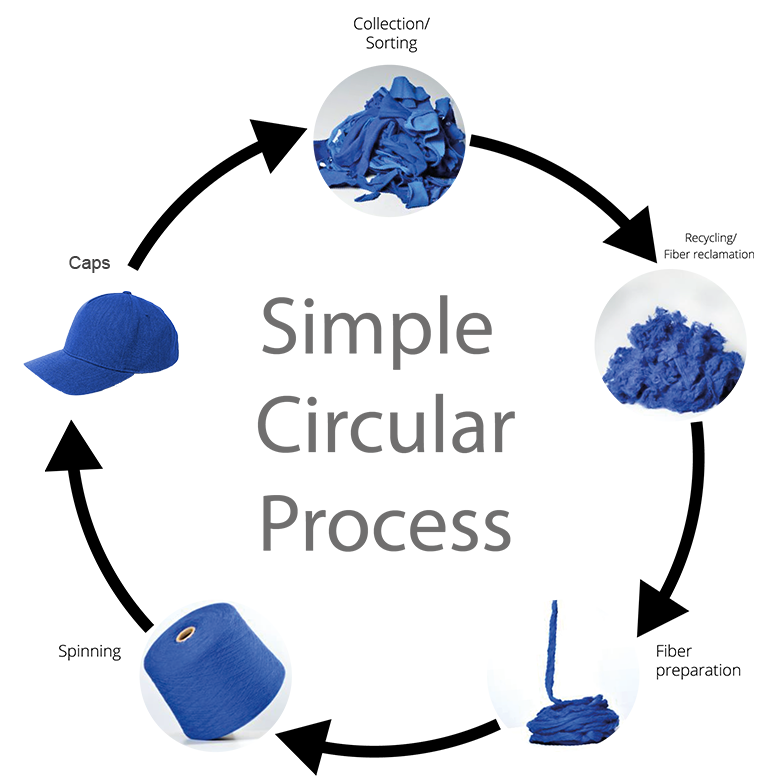

De-Carbon Headwear’s mission is to turn this waste into high-quality brand-new accessories.

De-Carbon Headwear with a fully compliant production facility that spans over an area of 15000 sft and with a production capacity of 500000 caps per month is working towards reducing your carbon footprint, to preserve the eco system for the future generation.

House-128 (2nd Floor), Road-01 (West Side)

Baridhara DOHS, Dhaka-1206

Bangladesh.

Email: connect@de-carbonheadwear.com

Phone: +8801894740700

Lengurdi, Araihazar,

Narayanganj, Bangladesh.

Phone: +880 1729949849

Aus Bangla Jutex

Mailing Address: 572 Le Parc Cir

Buffalo Grove, IL 60089

United States

Email: : connect@de-carbonheadwear.com

Phone: +1 (630) 344-3327